Customizable Categories

Customized Precision

The dimensional accuracy of custom bearings is critical. If the size is not right, it may cause project delays, equipment damage and a series of other problems. Accuracy is particularly critical for applications that require precise tolerances and smooth operation. Even small deviations can have a significant impact on performance and cost.

Customized Lubrication

Customized lubrication is essential for customers with special requirements. We will recommend the most suitable lubrication solution based on the customer's specific needs (such as temperature, speed, working environment conditions, etc.). This not only ensures the smooth operation of the customer's bearings, but is also crucial for future product maintenance.

Customized Materials

We offer a variety of materials to meet customer needs. These materials include but are not limited to:

● GCR15 steel

Known for its hardness and wear resistance.

● Polyurethane (PU), polyoxymethylene (POM), nylon (PA66)

Mostly due to the application of rubber on the outside of the bearing.

● 440C, 304, 316L stainless steel

Affordable price and excellent corrosion resistance.

● PEEK, PTFE

Wear resistance, low noise and corrosion resistance make it suitable for manufacturing bearing cages to improve bearing performance and reliability.

● Ceramics

These include materials such as silicon nitride (Si3N4), silicon carbide (SiC) and zirconium oxide (ZrO2) – all of which offer high temperature and wear resistance for demanding applications.

Customized Dimensions

We design and manufacture bearings in various sizes according to customer requirements to suit all types of applications.

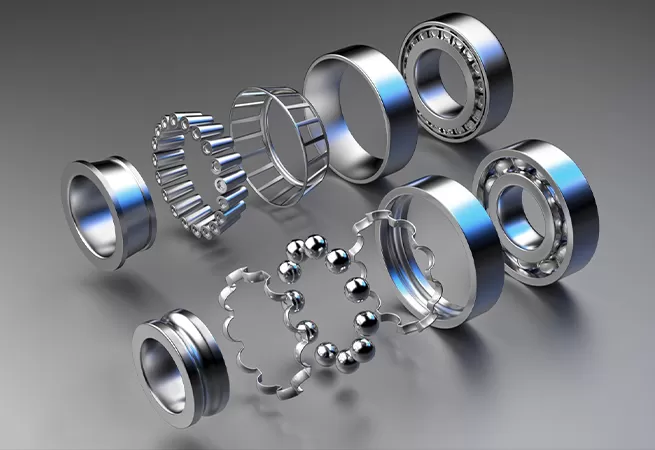

Customizable Bearing Types

With our rich experience and expertise, Rimao Bearings is able to provide various types of customized bearings to meet your specific configuration needs:

Get a Quote

Ball bearings

Very suitable for radial and axial loads and high speed requirements

Roller Bearings

Better suited for heavy-duty applications.

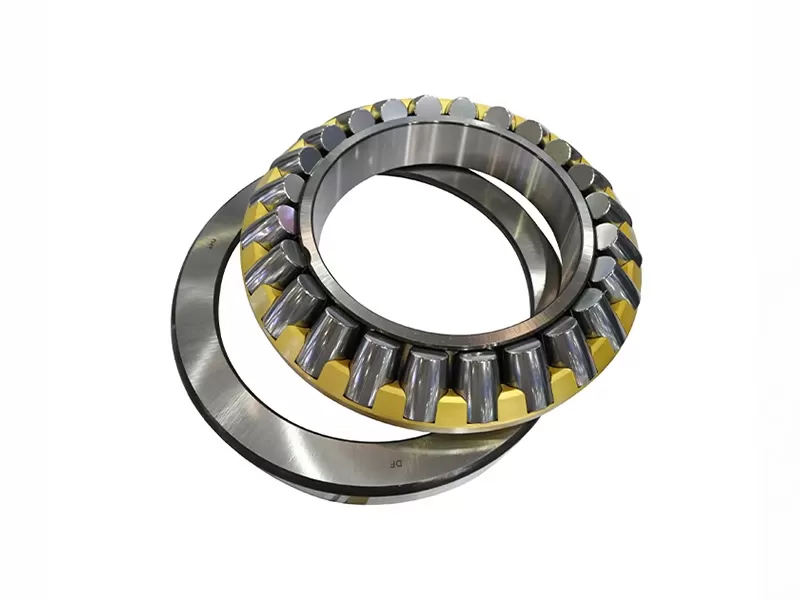

Slewing Bearing

Commonly used in large machinery and robots.

Slewing Bearing

Mainly used in rotary applications.

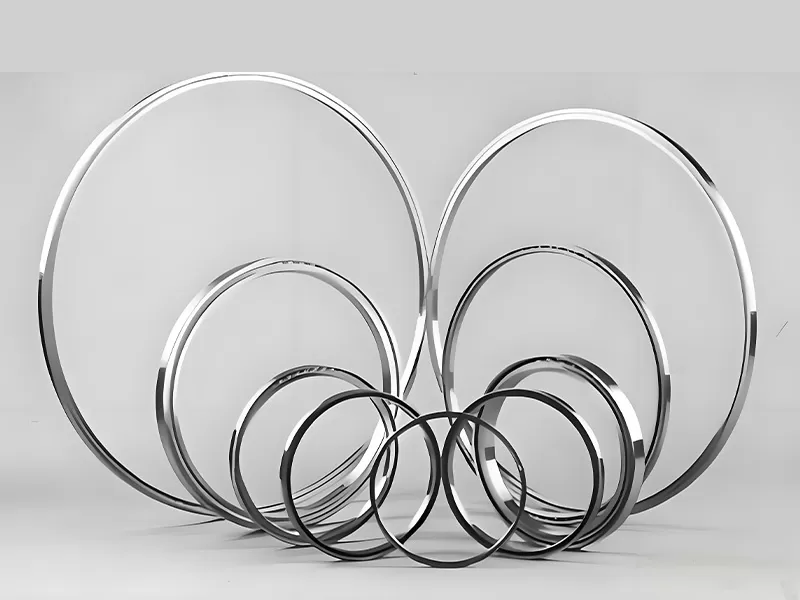

Thin Bearings

For use in tight spaces where absolute precision is required.

Miniature Bearings with Flange

Ideal for high precision, small scale applications.

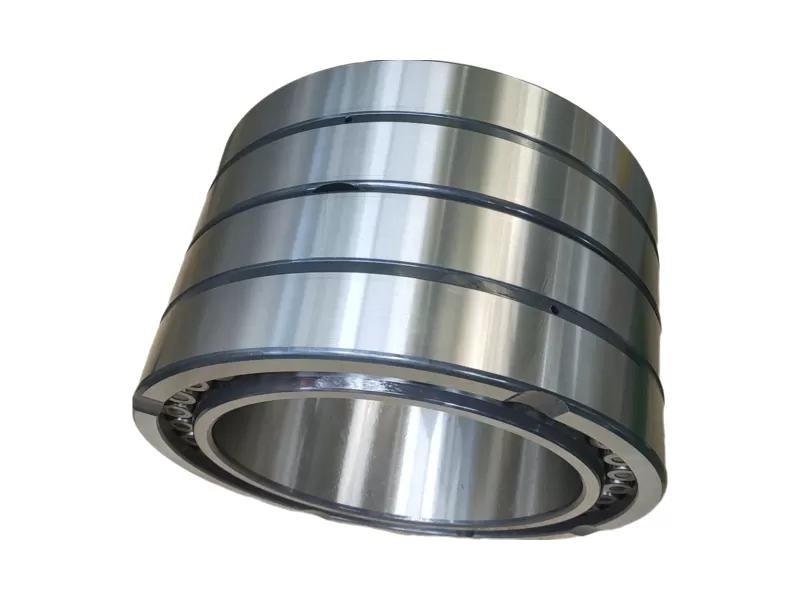

Rolling Mill Bearings

Very suitable for stable operation under high temperature and high load conditions.

Industries that Often Use Custom Bearings

Custom bearings are critical to a wide range of industries, each with unique requirements and challenges. Some of these key industries include:

Aerospace

Automotive

Industrial Machinery

Medical Devices

Emerging Fields

Customization Process

Customer Demand Analysis

Collect customer demand;

Analyze customer demand;

Determine bearing type and specifications.

Design Plan

Design bearing structure;

Determine material and heat treatment process;

Calculate bearing performance parameters.

Process Preparation

Prepare process documents;

Prepare fixtures;

Prepare tools and measuring tools.

Raw Material Procurement

Determine suppliers;

Procure raw materials;

Inspect raw materials.

Bearing Processing

Tuning;

Heat treatment;

Grinding; Superfinishing.

Bearing Assembly

Cleaning parts;

Assembling bearings;

Inspect assembly quality.

Bearing Inspection

Dimension inspection;

Appearance inspection;

Performance test.

Quality Control

Quality inspection;

Defective product handling;

Quality records.

Packaging and Delivery

Packaging bearings;

Marking and labeling;

Delivery to customers.

Why Choose Us

Choose us for bearing customization, you will get a reliable, efficient and economical partner

Efficient Production Equipment

Strict Quality Control

Continuous Innovation

After-sales Service

Environmentally Friendly

Our Customer Feedback